Event

LPKF, a leading manufacturer of laser and machine PCB Prototyping Machines and other advanced equipment for research and development and manufacturing, has announced they’ll be exhibiting in booth #1224 at the 2019 International Microwave Symposium

Resource

Looking to put together a business case for the purchase of your PCB prototyping machine? Get a big head start by downloading the LPKF Capex Justification Kit. This handy Word doc offers a complete template for writing up your request for purchase, and

Resource

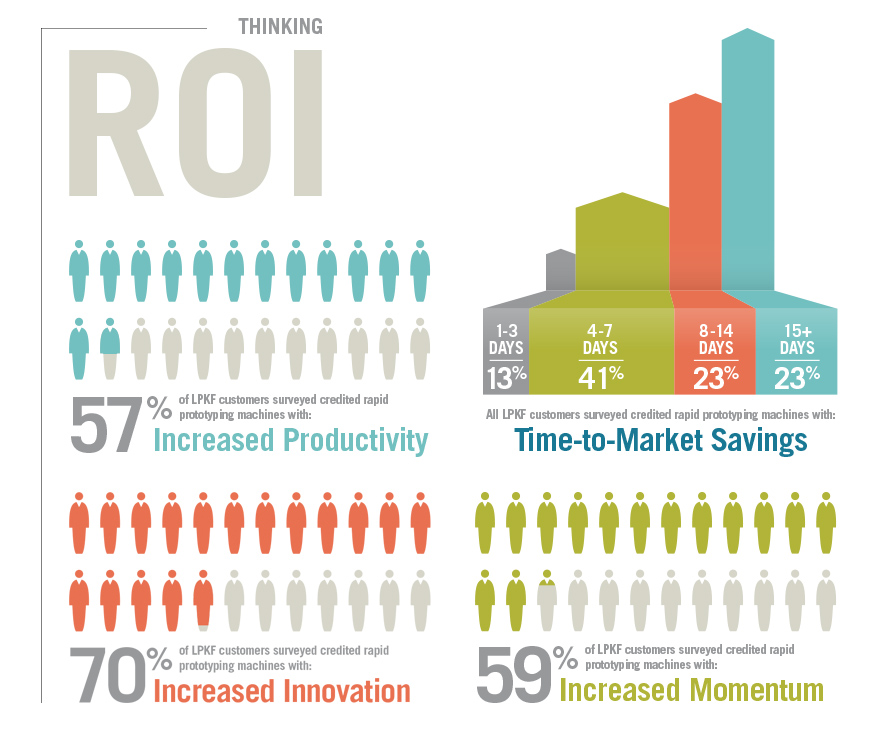

We have a library of customized formulas in Excel that can be used to plug in your PCB usage and cost numbers and calculate the real-time return on investment (ROI) of your PCB Prototyping Machine. If the corner office debates your approach to the numbers—you

Resource

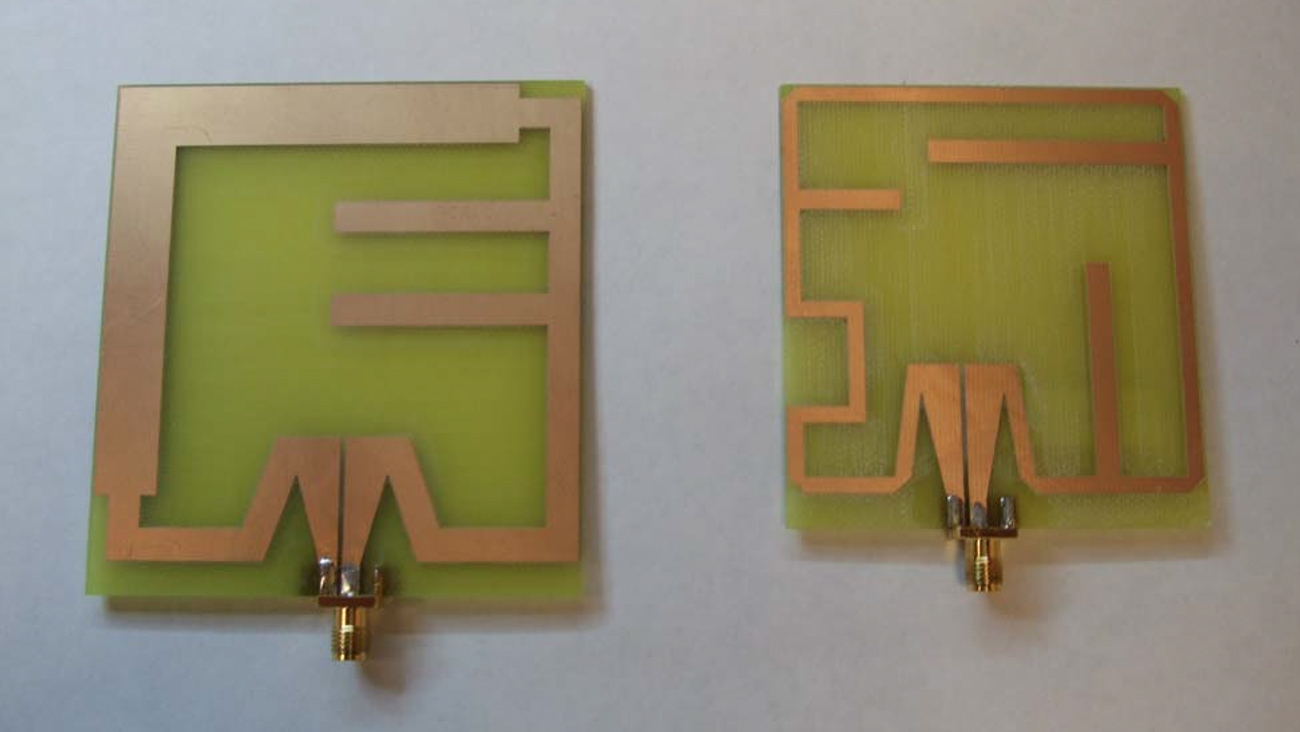

To stay ahead of the competition, PCB designers in RF/Microwave, wireless, IoT, and various other microelectronics and industrial fields must continuously evaluate the best new methods to produce efficient PCB circuits. While the list of potential PCB

Blog

With all the inherent benefits of bringing rapid PCB prototyping in-house widely known in every industry, one would think every product design team would have one by now. But the reality of suggesting any business expenditure over five or ten thousand

Blog

If after reading our blog, “How to write an effective business case for purchasing a rapid PCB prototyping machine", you’re ready to start preparing a business case for the acquisition of an LPKF machine for your lab, here is

Blog

If you are looking for an approach to rapid PCB prototyping, there is no shortage of potential in-house and outsource options. There are many different ways to get the job done, and all of them have been the most efficient method for somebody, somewhere,

Resource

Whether it is creating advanced electronics for automobiles or UAVs, manufacturers in a wide range of industries are turning to the practice of rapid PCB prototyping in their in-house labs to innovate and speed up a device's delivery to the market.

Blog

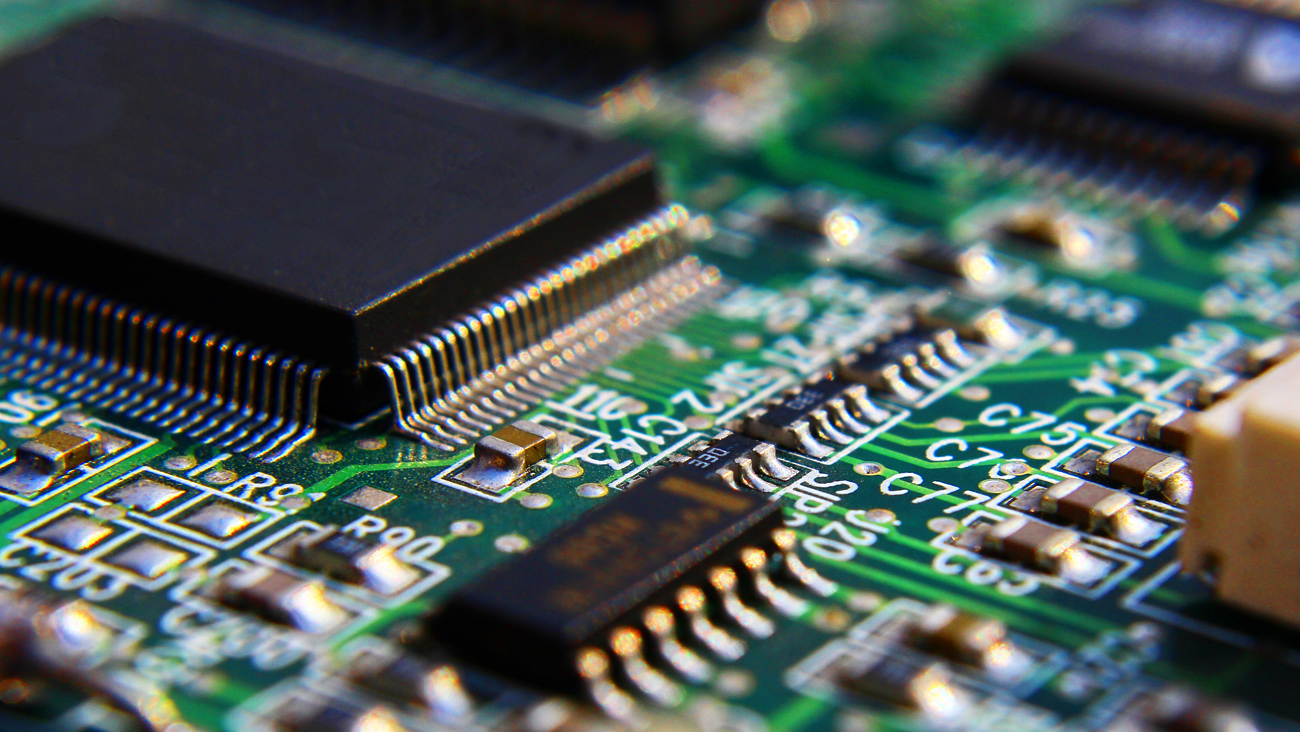

The way in which businesses design, develop, and manufacture products are always evolving—and the landscape of printed circuit board (PCB) design is no exception. Designing PCBs is an intricate process that requires highly skilled professionals

Spotlight

Challenge:

The fast-paced world of RF and Microwave Design often requires a certain amount of agility. As projects evolve, the ability to make last-minute design changes without compromising production schedules provides a significant competitive

Spotlight

Challenge:

Keeping up with competing demands of racecar engines with budgets of over $20 million per year for Formula One race cars, racing teams are always under immense pressure from sponsors and fans to perform at the highest level. As

Spotlight

Challenge:

For mid-size circuit board design companies, customization is king when it comes to winning and retaining customers. The ability to quickly provide reasonably priced solutions tailored to specific customers’ needs enables

Spotlight

Challenge:

In the world of circuit board design, it’s often difficult to strike a balance between quick production times and continued product innovation. Pushing the boundaries of innovation can require multiple design iterations,

Spotlight

Challenge:

Government agencies have long relied on in-house prototyping for circuit board design. Producing prototypes in-house allows organizations to turn projects around quickly and maintain confidentiality. Unfortunately, environmental

Spotlight

Challenge:

Hoping to explore the region further, Germany’s Fraunhofer Institute for Applied Solid State Physics, named after Joseph von Fraunhofer who investigated the properties of visible light as early as 1820, has enlisted the aid

Spotlight

Challenge:

Start-up companies understand that faster is usually better when it comes to circuit board design. This is especially true among companies whose products enable consumer electronics applications. Most designs require numerous

Blog

Although some companies choose to outsource design data to engineering consultants, getting a workable PCB out the door can be difficult to predict and can lead to costly mistakes. Here are some of the unexpected expenses associated with outsourcing

Blog

Prototyping is an extremely important step in the product development process and needs to be planned for and invested in wisely.

As the desire to innovate while also striving to beat competitors to market, the need for thoughtful

Blog

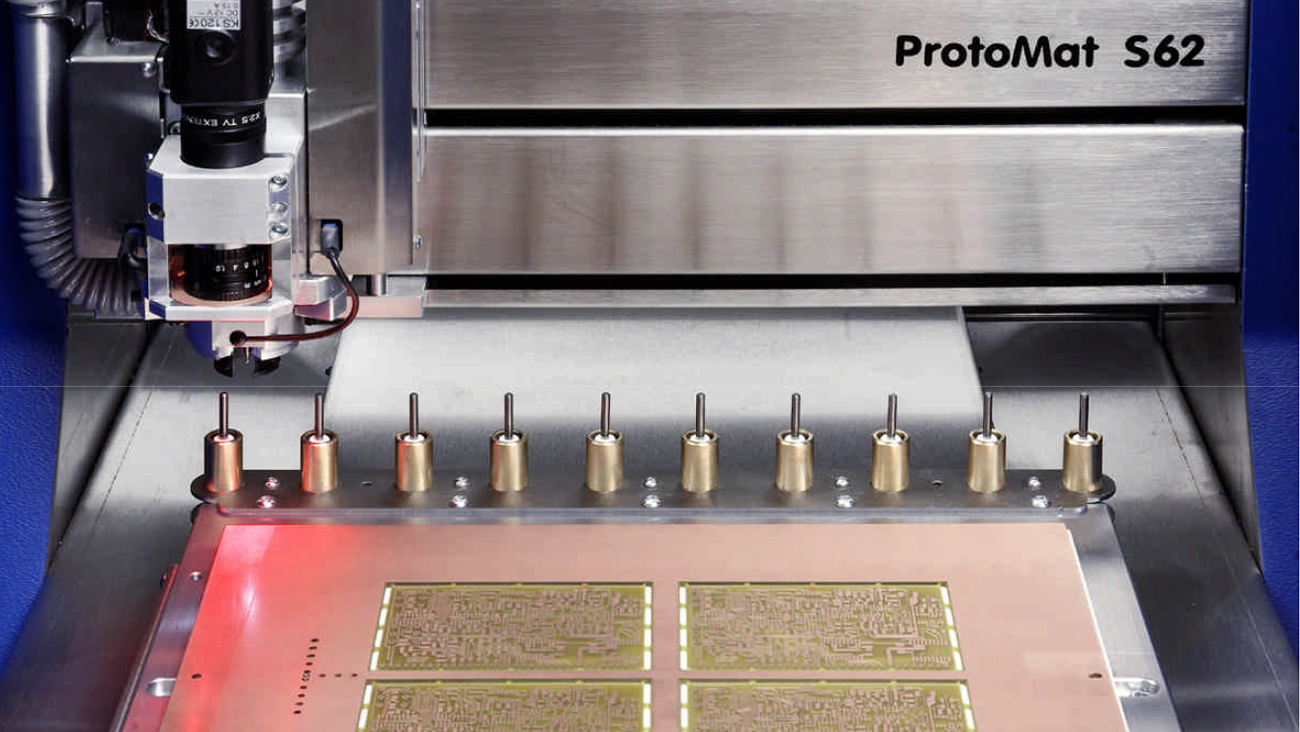

For the past 40 years, standard mechanical PCB milling systems have been the tools of choice for straightforward milling operations, and in some cases, they’ve been great performers for flex PCB etching as well. LPKF’s top-performing ProtoMat

Blog

In yesterday's prototype design process, a prototype was first designed in-house and then outsourced to a third-party PCB manufacturer. Today, innovative PCB design teams are convincing their companies to bring rapid PCB prototyping in-house. Here's

Blog

Problems with PCBs can happen after many years of use, or PCBs can have malfunctions mistakenly built into the board during manufacturing. Most PCBs problems are repairable thanks to their physical nature.

The following infographic outlines the most

Blog

History has proven that as technology evolves and becomes more refined, it also becomes more compact, powerful and accessible.

Over time, computers have become more advanced, portable, and most importantly, accessible. Development costs

Blog

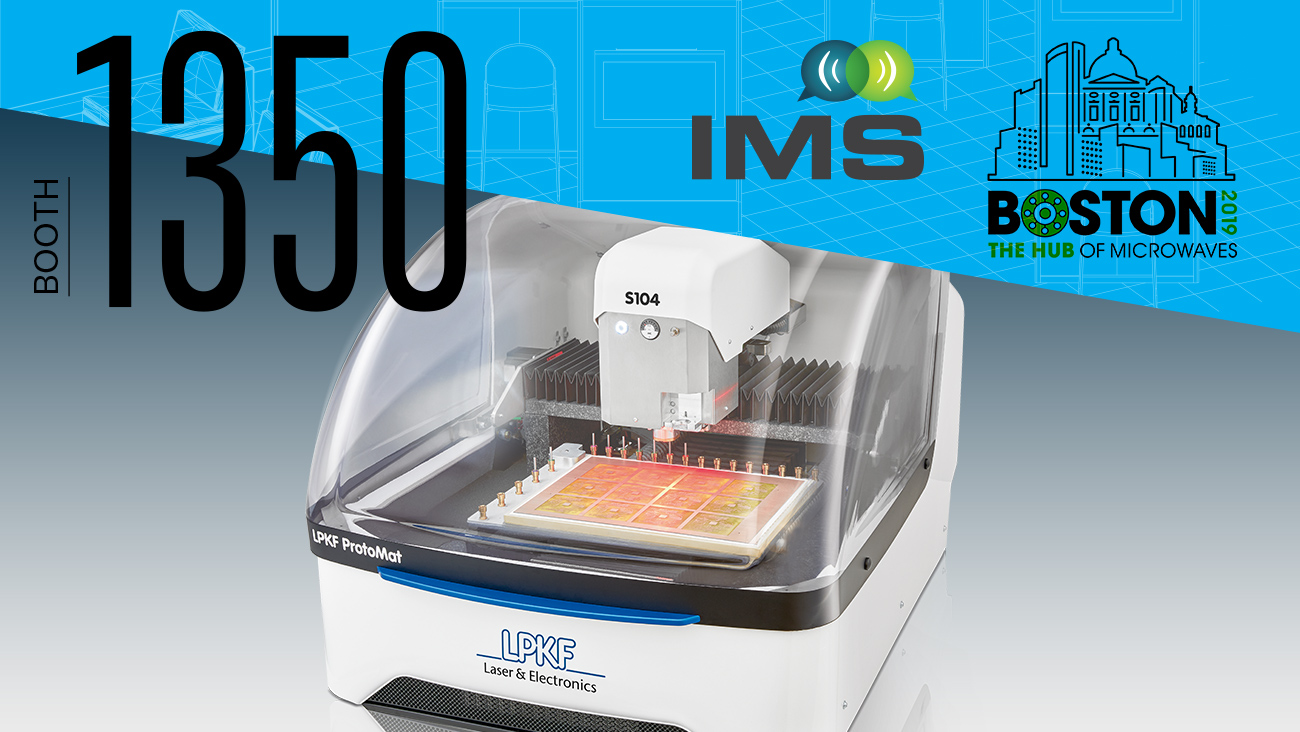

The ROI of an in-house PCB prototyping machine is easy to compute based on cutting out outstanding costs alone. But what's exciting to a manager who's glad they approved the capital equipment expenditure (CapEx) of a laser or mechanical